Consumers and business owners today have access to a wide range of packaging options and materials, making it much easier to achieve the desired packaging results.

Paper grade and paper weight are likely to come up at some point as you explore the world of custom packaging.

Some of the terminologies for paper weights and paper grades may seem foreign to you. But don’t worry, you will know how to read GSM and PT like a pro after reading this article.

Let’s dive into the various paper grades and weights you’ll need to know for packaging.

An Overview of Paperweight and Thickness

The strength of paper, as measured by its weight, indicates how well it will hold its shape when used as packaging.

As with many other units of measurement, the United States uses a different standard for calculating paper weight than the rest of the world.

In the United States, paperweight is classified according to its country of manufacture. However, elsewhere, a square unit of paper is used to measure weight.

GSM in Paper Weight

GSM is an abbreviation for grams per square meter and is used to express paper thickness. The length of the sheet is calculated based on the width of the sheet exactly one meter long.

There is no distinction between paper types or uses in the metric system.Rather, grammage describes how much one sheet of paper weighs when cut into a square measuring 1 x 1 meter. Due to the fact that the same size sheet is always weighed, regardless of its characteristics,so GSM (grams per square meter) is an easy way to measure paper thickness and weight.

Another way to measure paperweight is by LBS (pounds), but due to the fact that LBS alone does not adequately convey the weight of paper, and paper type is a key element when using LBS, so GSM is a better measurement for paperweights.

Here is a quick guide to converting GSM paperweights to pounds

- 100 GSM paper = 67 lbs

- 120 GSM paper = 81 lbs

- 200 GSM paper = 135 lbs

- 250 GSM paper = 168 lbs

- 300 GSM paper = 202 lbs

Paper Thickness

The paper’s weight is described by the measurement above, but its thickness is described by the point or caliper.

Using calipers, points are measured as 1/1000 of an inch . For example, 12-point paper is 0.012 inches thick.

PT (The Point System) is, at its core, a metric version of GSM, and both are used to calculate thicknesses.

In contrast, PT does not take into consideration the weight of the stock, but there are conversion charts that simplify this process.

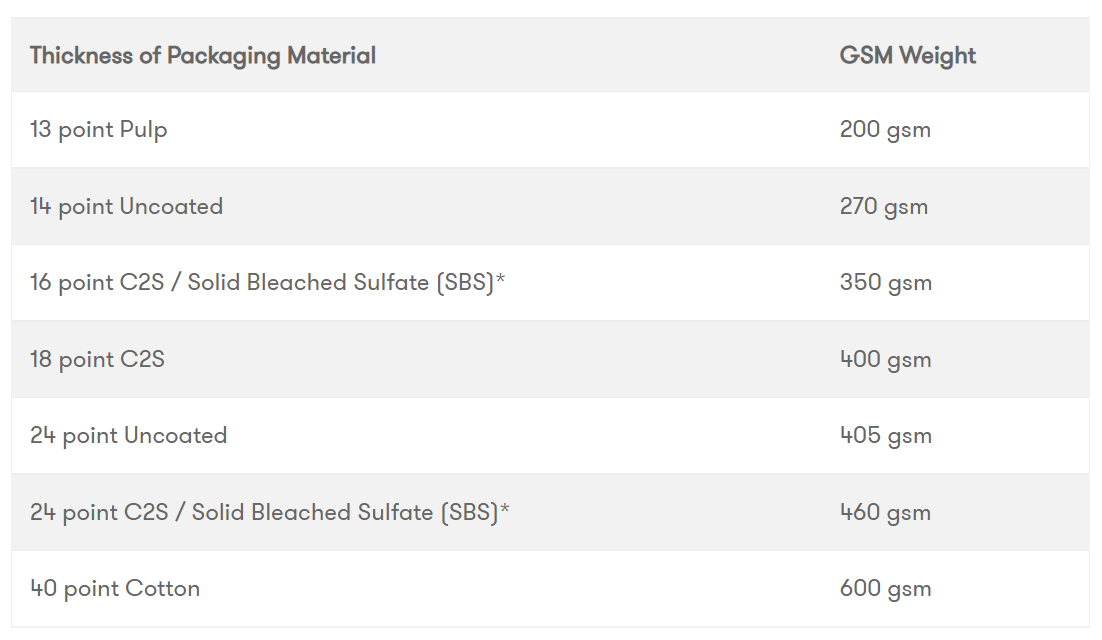

Here is a rough GSM to PT conversion chart to help you visualize how the process might look in your particular situation.

Be aware that these measurement systems become more complicated when comparing papers made by different paper manufacturers. Both sheets may seem identical at first glance, but their manufacturing processes may be very different.

Different Paperweights For Different Usage

You can see how different thicknesses of paper are used by looking at the chart below.

- 35 – 55 GSM paper: Most commonly used for newspapers.

- 90 – 120 GSM paper: This is the average weight of office paper or copy paper.

- 130 – 250 GSM paper: Most commonly used for promotional posters.

- 260 – 300 GSM paper: A thicker but still bendable card weight suitable for high-end brochures or magazines.

- 350 – 450 GSM paper: The heaviest and most rigid paper that stands easily under its own weight, which is why it is most commonly used for business cards and invitations.

Paper grades are determined by how the paper will be used. Here are some common paper grades used in printing and packaging:

CCNB (Clay Coated News Board)

These CCNB cartons are made from recycled newspapers, old corrugated containers, and a mix of other types of paper. CCNB is usually a board with a gsm range from 250-400 g/m2.

In many cases, CCNB printing is the most cost-effective and affordable option, but it has some drawbacks as well.

As this type of packaging absorbs a lot of moisture, you shouldn’t choose it if you’re concerned about moisture affecting your product. Foldable carton packaging is most often made with this type of paper.

In terms of paper grades, it isn’t exactly a fan favorite because the quality isn’t as good as other varieties, it can’t hold much product weight, and it’s more sensitive to moisture than other types. Even so, you can’t get anything easier, quicker, or cheaper than this if you need something fast, easy, and affordable.

Papers like this often hold pet food, detergent, or dry goods like noodles or beans.

FBB (The Folding Box Board)

Folding box board, or FBB, is crafted using a combination of chemicals and mechanical materials and processes. The weight is mostly between 200-340 g/m2.

This creates a pulp material that’s several layers thick which adds exceptional strength and durability. Because the chemical layer of this paper is bleached, it provides an exceptional canvas on which to create high-quality prints.

Even though this type of paper has a stiffer texture than other grades, it is a good choice for food, cosmetics, and pharmaceutical products as well.

SBS (Solid Bleached Sulfate Board)

A solid bleached sulfate material, commonly referred to as SBS, is the pinnacle of packaging. Its weight is usually more than 250 g/m2

Similarly to a folding box board, SBS is chemically pulped and then bleached. The bleached pulp is then shaped into boxes.

An SBS sheet can be coated on one side only (C1S) or on both sides (C2S).

In this grade of packaging, you can also use high quality specialty processes, such as spot UV printing, embossing, debossing, hot foil stamping, and embossing.

It’s no surprise that this type of custom packaging is popular in a wide range of industries, as it can be used to package anything from food to tobacco to personal care products.

SUS or CUK (Natural Kraft or Coated Unbleached Kraft )

SUS or CUK packaging is manufactured from 100% recycled materials, making it an ideal choice for environmentally-conscious companies.The grammage is normally 40–135 g/m2, higher grammage are available too.

The material can be applied to make the surface support even higher quality printing. A thin layer of kaolin clay can be applied to make the surface support even higher quality printing. It is an excellent option for food packaging and is extremely strong and tear-resistant.

Greyboard (CCNB Paperboard)

The Grey Board (also called chipboard, sometimes CCNB paperboard) is made by transforming recycled fibers into strong, flexible boards by transforming and compressing them. Since grayboard is made from recycled fibers, it has the characteristic ‘raw’ look that many recycled paper products have.

Grey boards are typically used to make rigid boxes. By measurement, their weights range from 1200gsm to 2000gsm in North America and Europe. For Chinese manufacturers, a measurement in MM is often used, like 1.5mm and 2mm.

Ford Paper and Ivory Paper

The most popular paper is Ford paper, which has a rough surface and is compatible with a variety of inks. The common quantitative is 70-80-90g/m2.

Ford is divided into 2 types:

White paper: This type of paper is very white (68% or more). It is commonly used for envelope printing, letterhead, photocopying in the office, and printing books.

Yellow paper: The advantage of this paper is that it is cheap due to its domestic production, and it has low whiteness (less than 60%).

Anothery similar paper is called ivory paper, the ivory paper is a two-sided paper with a smooth and rough side. It is an uncoated paper like Ford paper, but it comes in a wide range of weights, up to 450 gsm in weight. This type of packaging paper has a thicker texture and is stronger than Bristol paper(explained below). Due to its ability to print in full color and its safety for containing and keeping food, ivory packaging is widely used in packaging.

Recommended next reads

Why are there so many ways of measuring paper!?

News and Paper Reel Cargo Damage: A Formulaic Approach

V2RT Insurtech Solutions Pvt Ltd 7 months ago

Marketers – Cost Benefit of Reducing Paper Weight

Couche Paper

The surface is glossy and smooth. It has a high hardness, giving nice effects. It is often used to print brochures, catalogs, magazines, and posters. The weight is about 90-300g/m2.

A matte Couche is also available, which is used primarily in images of people, and portraits, for the purpose of high-resolution printing.

Bristol Paper

It is commonly found at 230 – 350 g/m2, has a slightly glossy surface, is smooth, and is compatible with inks, so it is widely used for soap, cosmetics, pharmaceutical boxes, shirt covers, brochures, cards, leaflets, posters, and wedding cards.

Duplex Paper

A duplex’s surface is similar to that of Bristol, while its reverse side is usually dark because it resembles a pasteboard. With a quantitative of over 300 g/m2, duplex is often used to make large boxes for products that require durability, hardness, and sturdiness.

Decal Paper

Decals have one side for printing and the other side covered with glue. They must be rolled in glossy film to protect the ink layer and increase color. Common types of decal include

- A paper decal means the first layer of the printing surface is made of paper.

- A plastic decal consists of a printing surface (layer 1) made from clear plastic or milky white plastic.

- A fragile decal is one whose printed side is made of special paper, very fragile. When affixed to a product, it cannot be removed intact.

- A glossy decal with a lot of colors.

- An art decal is made of art paper.

Start Your Packaging Project with the Right Grade of Paper

It’s understandable that you feel overwhelmed or confused by the different grades and weights of paper and which is best for retail packaging. Plus, you can choose from a variety of finishes, applications, and specialty printing options.

Ketsana Pack makes all things packaging our business, so you don’t have to worry about paper grades and weights. You don’t need to deal with the uncertainty of paper grades and weights on your own. We can provide you with a free no-obligation quote if you have questions, are unsure what options to choose or want more information about the types and grades of paper we offer.

We’ll take the time to better understand your project and your vision for your product packaging design, and then help you create a look that’s durable, attractive, and attention-grabbing, so you can focus on marketing and selling, while we take care of packaging design and printing.

Contact us today to get your packaging projects started.

————————————————————————————————————–